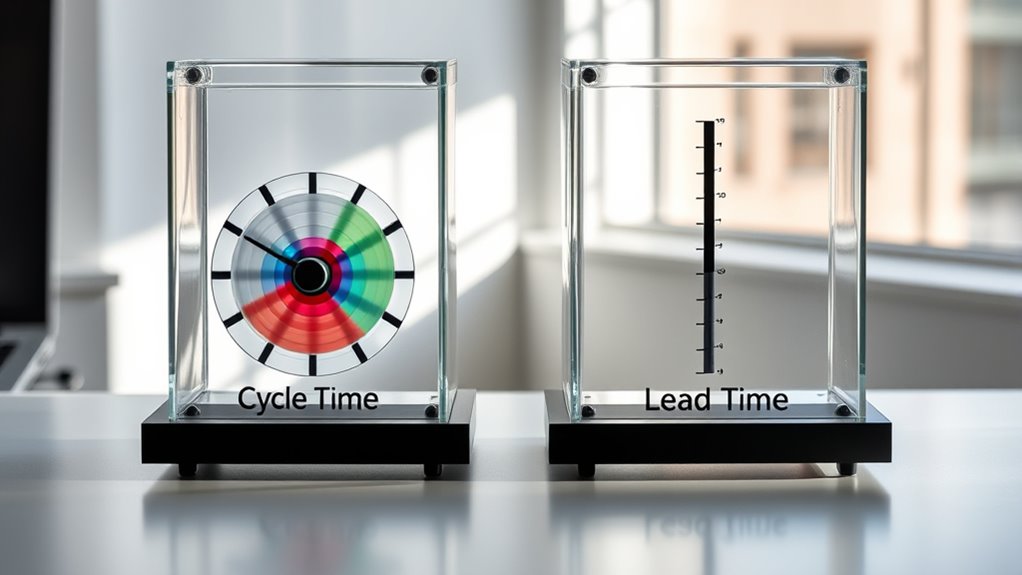

Cycle time measures how long it takes to complete a specific task or produce one unit, focusing on individual process steps. Lead time, on the other hand, spans the entire process from start to finish, including any waiting and delays. While reducing cycle time boosts efficiency, shortening lead time improves overall responsiveness. Knowing the difference helps you optimize workflows better; if you want to explore how these metrics can improve your processes, keep exploring the details.

Key Takeaways

- Cycle time measures the duration to complete a specific task or unit, while lead time tracks the total time from request to completion.

- Cycle time focuses on individual process steps, whereas lead time covers the entire process flow, including delays and waiting periods.

- Reducing cycle time improves process efficiency; shortening lead time enhances overall responsiveness and customer satisfaction.

- Cycle time helps identify delays within specific tasks, while lead time reveals broader bottlenecks across the entire process.

- Both metrics are essential for comprehensive process management but serve different purposes in measuring performance.

Understanding the difference between cycle time and lead time is essential for managing your workflow effectively. When you’re aiming to improve process efficiency and ensure smooth project management, knowing how these two metrics differ helps you identify bottlenecks and optimize your operations. While they both measure time, they serve distinct purposes and provide different insights.

Cycle time refers to the amount of time it takes to complete a specific task or produce a single unit of work from start to finish. Think of it as the speed of your process—how quickly you can go from beginning to completion on a particular activity. For example, in a manufacturing setting, cycle time might measure how long it takes to assemble one product. In project management, it could be the time to complete a single development cycle or task. Focusing on cycle time allows you to evaluate process efficiency for individual steps, helping you identify areas where delays or inefficiencies occur. Reducing cycle time often leads to faster throughput, improved productivity, and better resource utilization.

Cycle time measures how long it takes to complete a task or produce a unit from start to finish.

Lead time, on the other hand, encompasses the total duration from when a request or order is made until it’s fully delivered or completed. It captures the entire customer or stakeholder experience, including waiting periods, approvals, and any delays beyond the actual work. If you’re managing a project, lead time might span from the moment a client requests a service until they receive the final deliverable. In supply chain management, it covers all steps from order placement to delivery. Understanding lead time helps you grasp the overall responsiveness of your process, allowing you to set realistic expectations and improve customer satisfaction. Additionally, local legal knowledge can significantly influence lead time in divorce cases, impacting how quickly proceedings move forward.

The key difference lies in scope: cycle time zeroes in on how long individual tasks take, while lead time considers the entire process flow from request to delivery. When you’re looking to enhance process efficiency, reducing cycle time can make your workflow more agile and responsive. However, if your goal is to improve project management or customer experience, decreasing lead time might be more impactful, as it ensures quicker turnaround from start to finish.

Frequently Asked Questions

How Can I Reduce Cycle Time Without Affecting Quality?

To reduce cycle time without affecting quality, focus on process optimization by identifying and eliminating bottlenecks. Streamline workflows and automate repetitive tasks where possible. Also, improve resource allocation by ensuring your team has the right skills and tools to work efficiently. Regularly monitor performance metrics to make data-driven adjustments, maintaining quality standards while speeding up production. This balanced approach helps you achieve faster cycle times without compromising quality.

Which Metric Is Better for Measuring Customer Satisfaction?

You should prioritize satisfaction metrics to measure customer satisfaction effectively. These metrics, driven by customer feedback, directly reflect how well your products or services meet their needs. By actively collecting and analyzing customer feedback, you gain valuable insights into satisfaction levels. Satisfaction metrics give you a clear picture of customer happiness, helping you identify areas for improvement and enhance overall experience, ensuring long-term loyalty and success.

How Do Cycle Time and Lead Time Impact Project Planning?

You can improve project planning by understanding how cycle time and lead time impact your process optimization and resource allocation. Shorter cycle times let you identify bottlenecks quickly, enabling you to adjust resources efficiently. Lead time helps you set realistic deadlines and expectations. By tracking both, you guarantee smoother workflows, better forecasting, and more effective resource use, ultimately leading to more successful project completions.

Can Improving Lead Time Influence Overall Business Profitability?

You might think improving lead time won’t change profitability, but it truly can. Faster lead times mean better inventory management, reducing excess stock and costs. When you invest in process automation, you streamline workflows, cut delays, and deliver products quicker. This boosts customer satisfaction, drives sales, and ultimately increases your bottom line. So yes, refining lead time directly impacts your business’s profitability by making operations more efficient and responsive.

What Tools Are Most Effective for Tracking These Metrics?

You should use tools like Kanban boards and time tracking software to effectively monitor cycle and lead times. Kanban boards help you visualize workflow and identify bottlenecks, while time tracking software provides precise data on task durations. Combining these tools allows you to pinpoint inefficiencies, optimize processes, and improve overall productivity. Regularly reviewing these metrics helps you make informed decisions that boost your business’s efficiency and profitability.

Conclusion

Understanding the difference between cycle time and lead time helps you optimize your workflow effectively. Did you know that reducing cycle time by just 20% can increase productivity by up to 25%? By focusing on these metrics, you gain clearer insights into your processes and identify areas for improvement. Keep tracking both to streamline your operations and deliver value faster, ultimately boosting your team’s efficiency and customer satisfaction.