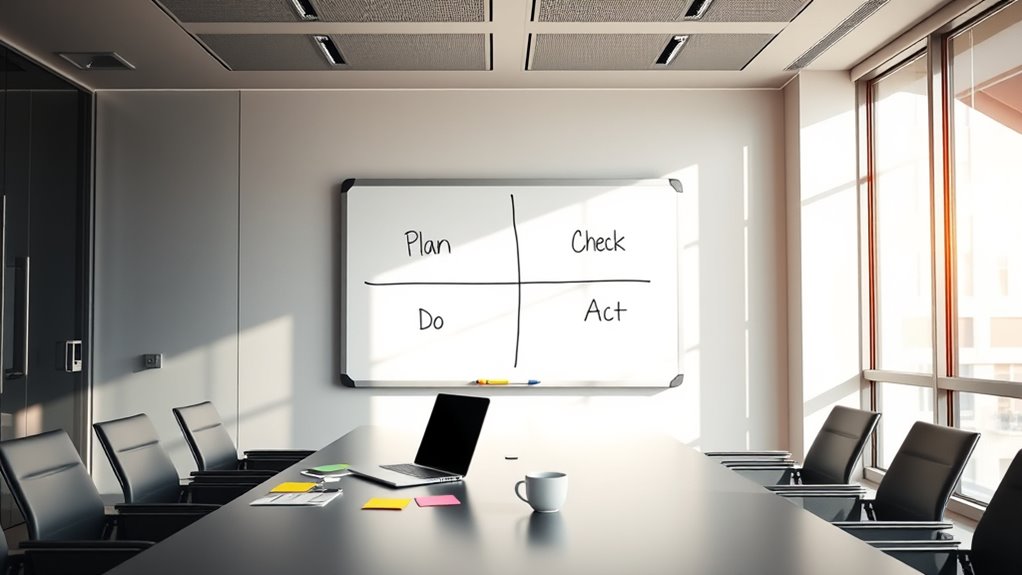

The PDCA cycle—Plan, Do, Check, Act—guides you through continuous improvement by systematically planning a change, testing it on a small scale, reviewing the results, and acting to implement successful strategies. As you follow this structured approach, you identify opportunities, monitor performance, and refine your processes iteratively. Mastering this cycle helps boost efficiency and solve problems effectively. If you keep exploring, you’ll discover how to apply PDCA in various organizational settings.

Key Takeaways

- The PDCA cycle is a continuous improvement process involving four phases: Plan, Do, Check, and Act.

- It helps organizations identify issues, implement solutions, evaluate results, and standardize successful practices.

- The cycle promotes iterative testing and refinement to optimize processes and performance.

- During the Plan phase, specific objectives and data collection set the foundation for effective action.

- The cycle’s feedback loop enables ongoing learning and adaptation for sustained organizational growth.

Have you ever wondered how organizations continuously improve their processes and achieve better results? The answer often lies in the PDCA cycle — a powerful tool for driving continuous improvement and process optimization. This cycle provides a structured approach to problem-solving and performance enhancement, enabling you to make meaningful changes that stick. When you adopt the PDCA cycle, you create a feedback loop that fosters ongoing learning and adaptation, which is essential in today’s fast-paced environment.

The first phase, Plan, is where you identify an opportunity for improvement. You analyze the current process, gather data, and define clear objectives. By planning carefully, you set a solid foundation for success, ensuring your efforts are targeted and effective. This step involves asking critical questions: What’s the problem? What are the desired outcomes? What resources are needed? When you approach process optimization with a strategic mindset, the plan becomes a roadmap that minimizes risks and maximizes gains. It’s important to document your plan thoroughly, so everyone involved understands the goals and the steps necessary to achieve them.

Next comes Do, where you implement the plan on a small scale or in a controlled environment. This phase allows you to test changes without risking the entire system. As you execute, it’s essential to monitor how the new processes perform, gathering real-time data and noting any issues that arise. Acting quickly to address these issues helps you refine your approach and avoid bigger problems down the line. The Do phase is about turning your plan into action, but it also requires flexibility to adapt as you learn from the implementation.

Following implementation, Check involves reviewing the results against your original objectives. You analyze the data collected during the Do phase to determine whether the changes led to improvement. Did process efficiency increase? Were customer satisfaction levels higher? Were costs reduced? This step is fundamental because it provides insights into what works and what doesn’t. If the results aren’t satisfactory, you identify gaps and areas for further adjustment. If they are positive, you’re ready to move forward with confidence.

Finally, Act is about standardizing successful strategies and planning the next cycle of improvement. If your changes proved effective, you implement them on a broader scale and document new procedures. If not, you revisit your plan, make necessary adjustments, and start the cycle again. This iterative process keeps your organization moving forward, continuously pushing for better process optimization and performance excellence. The PDCA cycle isn’t a one-time effort; it’s a mindset that encourages ongoing learning and development, helping you stay competitive and responsive to change. Incorporating a structured approach like PDCA ensures that improvements are sustainable and aligned with organizational goals.

Frequently Asked Questions

How Can PDCA Be Integrated With Other Management Tools?

You can integrate PDCA with other management tools by aligning it with processes like Six Sigma or Lean to enhance process integration. Use PDCA for continuous improvement, applying its cycle to identify issues, implement solutions, and monitor results. Combining these tools helps streamline workflows, promote data-driven decisions, and foster a culture of ongoing development, ultimately increasing efficiency and effectiveness across your organization.

What Industries Benefit Most From the PDCA Cycle?

Imagine a steam engine powering progress—this is how industries like manufacturing and healthcare excel with the PDCA cycle. You benefit most by applying it to manufacturing excellence and healthcare improvement, as it helps identify issues, implement solutions, and refine processes continuously. This proactive approach keeps operations efficient and patient care premier, making it ideal for sectors where quality and safety matter most.

How Do You Handle Resistance to Change During PDCA Implementation?

You handle resistance to change by focusing on effective change management and stakeholder engagement. Communicate clearly about the benefits, listen to concerns, and involve key stakeholders early in the process. By fostering transparency and collaboration, you build trust and reduce resistance. Encourage feedback, address doubts promptly, and highlight quick wins to demonstrate progress. This approach helps everyone stay committed and smooths the way for successful PDCA implementation.

What Are Common Mistakes to Avoid When Applying PDCA?

You should avoid miscommunication pitfalls by clearly defining roles and expectations at each step, guaranteeing everyone stays aligned. Don’t fall into overconfidence errors by assuming your initial plan is flawless; instead, regularly review and adapt. Skipping checks or rushing through phases can also hinder progress. Stay open to feedback, communicate effectively, and continuously refine your approach to prevent common mistakes and ensure successful implementation.

How Can PDCA Be Scaled for Large Organizations?

Did you know that 70% of large organizations struggle to scale PDCA effectively? To succeed, you should adopt scaling strategies that promote organizational alignment. Break down processes into manageable units, guarantee leadership commitment, and foster open communication across teams. Use these strategies to embed continuous improvement into your organization’s culture, enabling you to apply PDCA at every level and drive sustainable growth.

Conclusion

Just like a skilled navigator adjusts their course with each new wave, the PDCA cycle helps you refine your processes step by step. By planning carefully, doing diligently, checking your results, and acting on what you’ve learned, you continuously improve. Embrace this cycle as your reliable compass, guiding you towards better outcomes. Remember, consistency in applying PDCA turns small improvements into big successes, much like how tiny drops create a mighty river.